How to produce carbon nanotubes? How to produce carbon nanotubes?

Release date:2017-06-01 14:19:00How to produce carbon nanotubes? How to produce carbon nanotubes?

Release date: June 1, 2017 reading times: 74

What is carbon nanotubes?

Carbon nanotubes (CNTs), also known as Ba based tubes, are one-dimensional quantum materials with special structures (radial size is nanometer, axial size is micron, and both ends of the tubes are basically sealed).Carbon nanotubes are mainly composed of hexagonal carbon atoms, which form several to dozens of concentric tubes.The distance between layers is about 0.34nm, and the diameter is generally 2 ~ 20nm.According to the different orientation of the carbon hexagon along the axial direction, it can be divided into three types: zigzag, armchair and spiral.Among them, helical CNTs have chirality, while zigzag and armchair CNTs have no chirality.

What are the applications of carbon nanotubes?

As the material of touch screen.In the previous technology, scientists used powdered carbon nanotubes to prepare solutions and directly coated them on pet or glass substrates, but such technology has not entered the stage of mass production so far; at present, the technology of super aligned carbon nanotubes can be successfully mass produced; the technology is to directly extract the film from a super aligned carbon nanotube array and lay it on the substrate to make a transparent conductive film, just like from cottonThe yarn is drawn out of the strip.The core of this technology, the super aligned carbon nanotube array, is a new material first discovered by Beijing Tsinghua Foxconn nano center in 2002

Preparation of carbon nanotubes

The common preparation methods of carbon nanotubes are arc discharge, laser ablation, chemical vapor deposition (hydrocarbon pyrolysis), solid-phase pyrolysis, glow discharge, gas combustion and polymerization synthesis.

CVD vacuum atmosphere tube furnace

CVD vacuum tube furnace is widely used in high, medium and low temperature CVD processes, such as the development of carbon nanotubes, coating of crystalline silicon substrate, controlled growth of nano zinc oxide structure, etc. it can also be applied to diffusion welding of metal materials and heat treatment in vacuum or protective atmosphere

CVD vacuum atmosphere tube furnace adopts high-purity quartz tube or corundum tube as the inner furnace, which is detachable and sealed in three sides, with good cleanliness and vacuum degree

The fire-resistant and thermal insulation materials of CVD vacuum tube furnace are all made of advanced light fiber products, with light weight and low energy consumption

The heating element of CVD vacuum atmosphere tube furnace is U-shaped silicon molybdenum rod or imported resistance wire. The temperature control system is controlled by imported multi-stage intelligent program temperature controller. The temperature control has good stability and repeatability

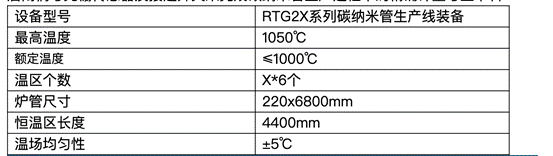

Carbon nanotube production line equipment -- rtg2x series carbon nanotube production line equipment

Rtg2x series carbon nanotube production line equipment is mainly designed for the production and experiment of carbon nanotubes, and colleagues are also used for other carbon material processes.

RTG2X series of carbon nanotubes production line equipment has been jointly developed with a number of scientific research institutes, with strong pertinence and stable performance, and mass production of carbon nanotubes has been realized.

Rtg2x series carbon nanotube production line is equipped with high-purity quartz tube furnace, which has good cleanliness, multi furnace structure and high production efficiency

Rtg2x series carbon nanotube production line is equipped with alumina fiber products for heat preservation, quartz tube and glove box for sealing, and fast cooling system

Rtg2x series carbon nanotube production line is equipped with an unattended automatic production line for automatic loading and unloading. It is a leading technology in China. It uses a self-made 5-axis manipulator and automatic switches, grating sensors and proximity switches to complete the accurate measurement and loading and unloading in the production process of carbon nanotubes

Contact information of carbon nanotube equipment manufacturer

Last article:第一頁

Next article:Successful development of Nippon new high temperature "graphene special furnace